High Speed UV Spot Coating Machine

Product Details:

- Product Type High Speed UV Spot Coating Machine

- General Use Industrial

- Weight (kg) 13750 Kilograms (kg)

- Coating Speed sq m/hr

- Automatic Yes

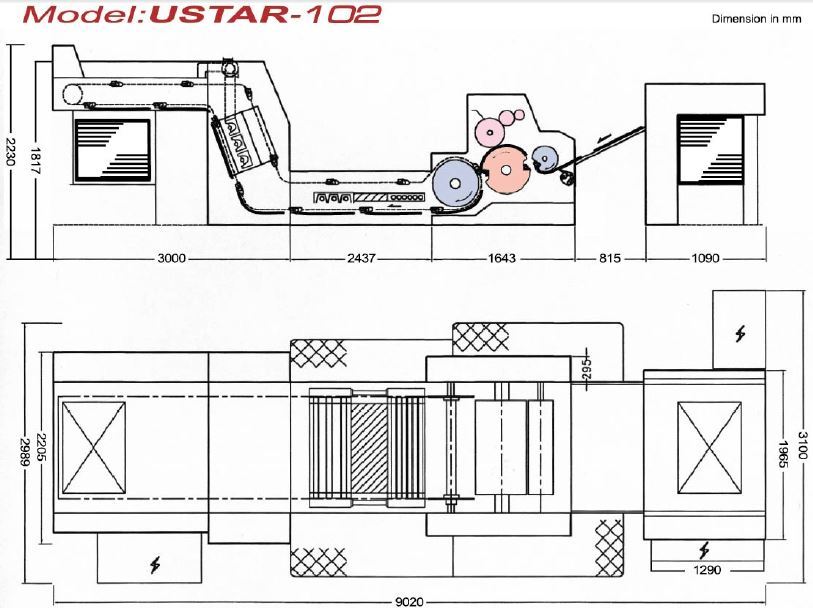

- Dimension (L*W*H) 9020 x 3100 x 2350 Millimeter (mm)

- Warranty 1 year

- Click to View more

High Speed UV Spot Coating Machine Price And Quantity

- 1 Set

High Speed UV Spot Coating Machine Product Specifications

- Industrial

- sq m/hr

- High Speed UV Spot Coating Machine

- 9020 x 3100 x 2350 Millimeter (mm)

- Yes

- 13750 Kilograms (kg)

- 1 year

High Speed UV Spot Coating Machine Trade Information

- Keelung Port, Taiwan

- 5 Set Per Month

- 3 Months

- Yes

- Contact us for information regarding our sample policy

Product Description

A High-Speed UV Spot Coating Machine is a particular piece of hardware utilized in the printing and completing industry to apply spot UV coatings to explicit areas of written words. Spot UV coating adds a reflexive and raised impact to specific components of the plan, making a striking difference between the covered and uncoated regions. This impact is usually used to improve the visual allure of specific plan components, like logos, pictures, text, or patterns. High-Speed UV Spot Coating Machines are generally utilized in the creation of different written words, for example, business cards, book covers, handouts, bundling boxes, and showcasing materials, where adding a bit of tastefulness and complexity can fundamentally improve the general plan and allure.

USTAR-102 FEATURES:

- Accurate spot coating registration with tolerance of +/- 0.5mm

- Double diameter impression cylinder reduces the surface tension of coating varnish, thus decreasing the roller marks but increasing gloss.

- Robust construction with 13 tons weight capable of 15000 cycles /hr.

- Offset configuration with under swing arm feeding system.

- Gears & shafts bearing in oil bath system while machine in production.

Equipment:

- High speed stream feeder

- Spot / full coater for UV varnish / water based (Aqueous) varnish coating

- Drying conveyor

- UV curing system

- IR drying system (option)

- Air condition (option)

- Delivery unit

Technical Specifications ofHigh Speed UV Spot Coating Machine:

|

Max. Sheet Size |

730 x 1030mm |

|

Min. Sheet Size |

340 x 406mm |

|

Coating area |

720 x 1020mm |

|

Paper thickness |

80-450gsm |

|

Machine Speed |

Up to 8800 Sheets / hour |

|

Dimension (LxWxH) |

9020 x 3100 x 2350mm |

|

Total Weights |

13750 kg |

|

Total Power required |

82.1(WB) / 58.1 (UV) kw |

Precise and Efficient Coating Solution

The High Speed UV Spot Coating Machine delivers superior spot coating with remarkable speed and uniformity. Its advanced UV technology enhances printed surfaces with precise gloss accents, heightening visual quality and protection. Fully automated, it simplifies bulk operations and increases productivity, making it ideal for industrial-scale usage.

Robust Build with Extensive Coverage

Constructed to accommodate demanding workflows, this machine boasts a solid frame weighing 13,750 kg and ample dimensions (9020 x 3100 x 2350 mm). Its design enables operation on a wide variety of materials and ensures both longevity and minimal downtime, making it a valuable asset in large printing and packaging facilities.

Regional Reliability and Warranty

Sourced from Taiwans skilled industry suppliers, this fully automatic UV spot coating solution is available through distributors, exporters, manufacturers, and traders. Users benefit from a 1-year warranty, which guarantees support and peace of mind for those relying on continuous production capabilities.

FAQs of High Speed UV Spot Coating Machine:

Q: How does the High Speed UV Spot Coating Machine operate automatically?

A: This machine utilizes programmed controls and automated feeders to apply UV spot coatings without requiring manual intervention. Operators simply set up the parameters, and the equipment handles the coating, curing, and loading processes efficiently.Q: What types of products can this UV spot coating machine process?

A: The machine is versatile, designed to handle a range of industrial printed materials such as brochures, packaging, labels, and posters, adding high-gloss or matte spot-UV finishes to designated areas for enhanced appearance and texture.Q: When is UV spot coating most beneficial in production?

A: UV spot coating is particularly advantageous during the finishing stage of print production, where clients desire both visual impact and added durability for their printed items. The process protects products and enhances their marketability.Q: Where is this machine ideal for use?

A: The High Speed UV Spot Coating Machine is best suited for large-scale industrial environments like commercial printing plants, packaging factories, and facilities that require high-volume, high-quality finishing solutions.Q: What are the main benefits of using a fully automatic UV spot coating machine?

A: Automatic operation reduces labor requirements, increases production capacity, improves finish consistency, and minimizes material waste. These benefits lead to faster turnaround times and lower operational costs for industrial users.Q: How is maintenance handled under the 1-year warranty?

A: During the 1-year warranty period, maintenance and support are provided by the supplier. Operators can contact their distributor or manufacturer for prompt service, ensuring sustained optimal performance with minimal disruptions.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+