Automatic Flexo Printer Slotter

Product Details:

- Type Automatic Flexo Printer Slotter

- Material Mild Steel

- Capacity Customizable / As per requirement Kg/hr

- Computerized Yes

- Cutting Speed 180 sheets/ min m/m

- Cutting Size 1600 x 3600 mm

- Cutting Thickness 7-11 mm Millimeter (mm)

- Click to View more

Automatic Flexo Printer Slotter Price And Quantity

- 1 Set

- 2-11 mm

- 0.6-0.9 MPa

- 1.0 mm

- Available

- Tool Kit, Instruction Manual

- Gear Drive (Hardened & Ground Gears)

- Corrugated Board

- Flexographic

- 3 Color

- 140 mm

- Lead Edge Feeder

- <85 dB

- 180 sheets/min

- 150 sheets/min

- Touch Screen HMI

- Fan-based Cooling

Automatic Flexo Printer Slotter Product Specifications

- Customizable / As per requirement Kg/hr

- 44.6 kw for 3 color Watt (w)

- 7-11 mm Millimeter (mm)

- 14340 x 4850 x 3270 Millimeter (mm)

- 1600 x 3600 mm

- Mild Steel

- 25300 Kilograms (kg)

- 380V/415V Volt (v)

- Blue and Yellow

- Yes

- Automatic Flexo Printer Slotter

- 180 sheets/ min m/m

- 2-11 mm

- 0.6-0.9 MPa

- 1.0 mm

- Available

- Tool Kit, Instruction Manual

- Gear Drive (Hardened & Ground Gears)

- Corrugated Board

- Flexographic

- 3 Color

- 140 mm

- Lead Edge Feeder

- <85 dB

- 180 sheets/min

- 150 sheets/min

- Touch Screen HMI

- Fan-based Cooling

Automatic Flexo Printer Slotter Trade Information

- Keelung Port, Taiwan

- 5 Set Per Month

- 3 Months

- Yes

- Contact us for information regarding our sample policy

Product Description

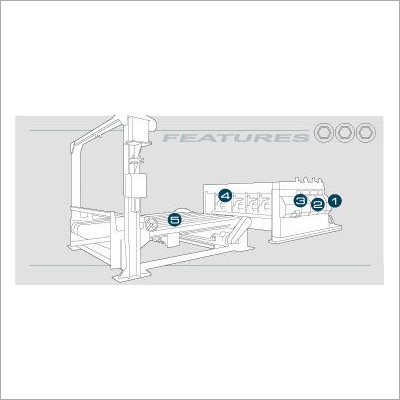

Our Automatic Flexo Printer Slotter is available with a great dimension, speed, weight and many more. Its printing is done by a rubber stereo and the stereo can be fixed on printing cylinder by using double side adhesive tape. It is engineered by our proficient experts who checked or inspected each material in its processing. It is easy to use and handle. Besides, its optional equipments are load edge feeder, rotary die cutting, computer system, ceramic anilox ink roll, etc. Also, the Automatic Flexo Printer Slotter is auto feeder which has Slotter & creaser, gluting, Folder Unit and squaring unit. It saves time, and has long life cycle.

An Automatic Flexo Printer Slotter is a refined machine utilized in the folded box fabricating industry. It is intended to carry out numerous roles automatically, including printing, opening, and alternatively rotational bite the dust cutting, in a solitary pass. This fast machine offers effectiveness and exactness in delivering ridged boxes, which are normally utilized for bundling different items. Automatic Flexo Printer Slotter machines are pivotal parts of current folded box fabricating offices. They assume an imperative part in satisfying the needs of different businesses, where hand crafted and very much printed bundling is fundamental for marking and item show.

Specification ofAutomatic Flexo Printer Slotter:

|

Specification |

Planet - 260 |

|

Machine Speed |

180 sheets/ min |

|

Max. Sheet size |

1150 x 2600 mm |

|

Max. Sheet size (with stop feed) |

1500 x 2600 mm |

|

Min. Sheet size |

310 x 630 mm |

|

Max. Printing area |

1150 x 2460 mm |

|

Max. Square box |

615 x 615 mm |

|

Min. Square box |

160 x 160mm |

|

Flexo plate thickness |

7 mm |

|

Dimension (LxWxH) |

14340 x 4850 x 3270 mm |

|

Total weight |

25300 kg |

|

Total power required |

44.6 kw for 3 color |

- Auto Feeder

- Printing unit (for 1st color)

- Printing unit (for 2st color)

- Printing unit (for 3st color)

- Slotter and creaser

- Gluting and Folder Unit

-

Squaring unit

- Load edge feeder

- Ceramic anilox ink roll

- Rotary die cutting

- Computer system

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+