Calendering Machine

Product Details:

- Frame Type Welded Rigid Frame

- Lubricating System Centralized Auto Lubrication

- Motor Power 15 HP Horsepower (HP)

- Connectivity Options Ethernet/USB

- Noise Level 75 dB db

- Frequency 50 Hz Hertz (HZ)

- Production Capacity 1200 kg/hr Kg/hr

- Click to View more

Calendering Machine Price And Quantity

- 1 Set

Calendering Machine Product Specifications

- 75 dB db

- Adjustable up to 120 kg/cm kgf/cm2

- 50 Hz Hertz (HZ)

- 1200 kg/hr Kg/hr

- 15 kW

- Blue/Grey

- Water-Cooled Rollers

- 380V Volt (v)

- Welded Rigid Frame

- Centralized Auto Lubrication

- 15 HP Horsepower (HP)

- Advanced Roller Technology

- Ethernet/USB

- 3200 x 1200 x 1750 mm Millimeter (mm)

- CM-3200HD

- 2800 kg Kilograms (kg)

- Industrial

- PVC/EVA/PP/PE/Rubber

- Calendering

- 0.05 mm mm

- Electricity

- Up to 220C Celsius (oC)

- Heavy duty frame, emergency stop, digital thickness display

- 15 kW Watt (w)

- Calendering Machine

- Polished

- Automatic

- AC Motor with VFD

Calendering Machine Trade Information

- Keelung Port, Taiwan

- 5 Set Per Month

- 3 Months

- Yes

- Contact us for information regarding our sample policy

Product Description

Calendering Machine

In addition to he VENUS series. TYMI machinery has developed In COMET series (aim whine which is robust in construction and yet versatile in design Bath series can be integrated together with automatic feeder and delivery unit to become a glass line system which can perform in- line calendaring. TYMIs Calendaring Medina (Comet series) Should work together with the Caring Machine News series. PVA calendaring vanish was coated on sheets via Coating Machine. Then sheets with PVA are metted by heat and pressure at heated plate at calendaring machine. The design at COMET calendaring machine emphasizes the heating performance on supplying proper heating energy and pressure to reach high gloss.

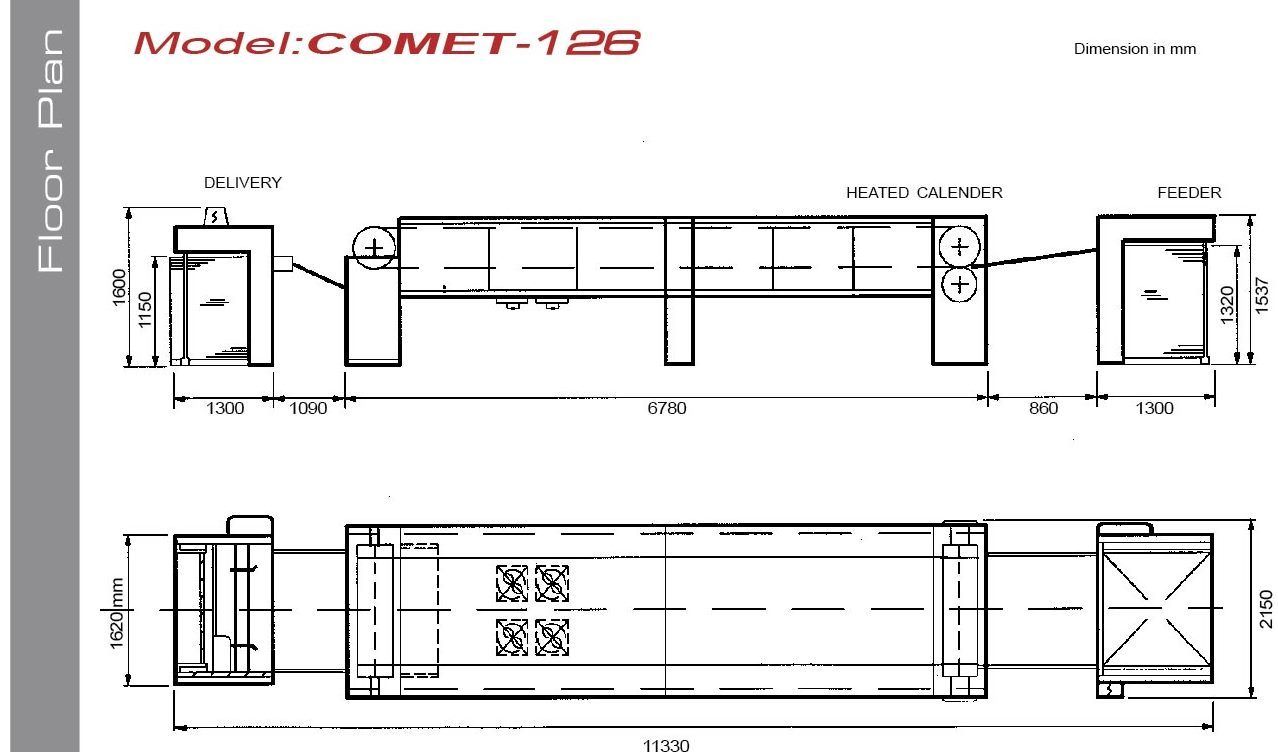

Comet-126 Features ofCalendering Machine:

- Frames structure and Impression cylinder are firm and steady

- Heater thermostat control, safety design.

- Optional gas heating system, electronic ignition system.

-

Hydraulic press device for pressure evenly.

Stream Feeder

- Feeder Suction Head With Maintenance Free Rotary Valve Requires No Lubricant Or Oil.

- The Feeder Can Be Adjusted While Running.

- Double Sheet Detector.

- Variable Speed For Adjustment To Different Kinds Of Sheet.

-

Braking System For Motor Drive To Minimize Paper Wastage.

Calendering Unit

- Consist of chromed calendering cylinder pressure cylinder and calendering belt

- Counter Pressure cylinder is coated With Special Hardened Synthetic Rubber To Stand High Pressure.

- Sturdily Constructed calendering cylinder To stand pressure Up To 250 kg/cmr

-

Precise thermostatic Control To maintain Constant Temperature.

Heated Conveyor

- Endless Stainless Steel Conveyor Belt.

- Electronic Photo-Cell For Safe-Guard.

-

Cooling Fan System.

Water-Cooling Device Optional

- Direct Water Cooling System Equipped At The End Of Conveyor Belt To Eliminate Cracking Of Paper Surface.

-

Moistening Roller With Cotton For Even distrubtion Of Water On Paper SurfaceExtended Conveying System With Independent Driving No Follow Separating Speed Of Sheets From Calendering Belt.

Delivery Unit

- Pneumatic Sheet Jogging Device Knocking Up Both Sides Of Sheet And Photo- Electric Cell controlled.

- Equipped With Sheet Gunner.

- Automatic Pile Raising And Lowing.

-

High Speed Sheet Guiding System Ensure Jogging Effect. Also Adjustable And Simple At Operation

Technical Specifications ofCalendering Machine:

|

Max. Sheet Size |

1200 x 1200mm |

|

Min. Sheet Size |

340 x 406mm |

|

Max. Working width |

1180mm |

|

Sheet thickness |

250-600gsm |

|

Conveyor Speed |

12-45 m/min |

|

Total Power required |

60.55 kw (Electrical heating type) |

|

Dimension (L x W x H) |

11330 x 2150 x 1600mm |

|

Total Weights |

6234 kgs |

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+