High Speed UV Spot Coating Machine (Conveyor Type)

Product Details:

- Product Type High Speed UV Spot Coating Machine

- General Use Industrial

- Material Mild Steel/Alloy Steel

- Type Other

- Weight (kg) Approx. 2200 kg Kilograms (kg)

- Coating Head High Precision Roller System

- Coating Width 20 24 (500 mm 620 mm) Millimeter (mm)

- Click to View more

X

High Speed UV Spot Coating Machine (Conveyor Type) Price And Quantity

- 1 Set

High Speed UV Spot Coating Machine (Conveyor Type) Product Specifications

- Approx. 10 14 kW Kilowatt (kW)

- UV/WB Coating

- Yes

- Max. 620 mm Millimeter (mm)

- Yes

- White

- UV Coating & Water-based Coating

- 380V / 415V, 3 Phase, 50 Hz Volt (v)

- Other

- High Precision Roller System

- Max. 620 mm Millimeter (mm)

- Approx. 4300 x 1550 x 1300 mm Millimeter (mm)

- Approx. 2200 kg Kilograms (kg)

- High Speed UV Spot Coating Machine

- Mild Steel/Alloy Steel

- 20 24 (500 mm 620 mm) Millimeter (mm)

- Electric

- Industrial

High Speed UV Spot Coating Machine (Conveyor Type) Trade Information

- 5 Set Per Month

- 3 Months

Product Description

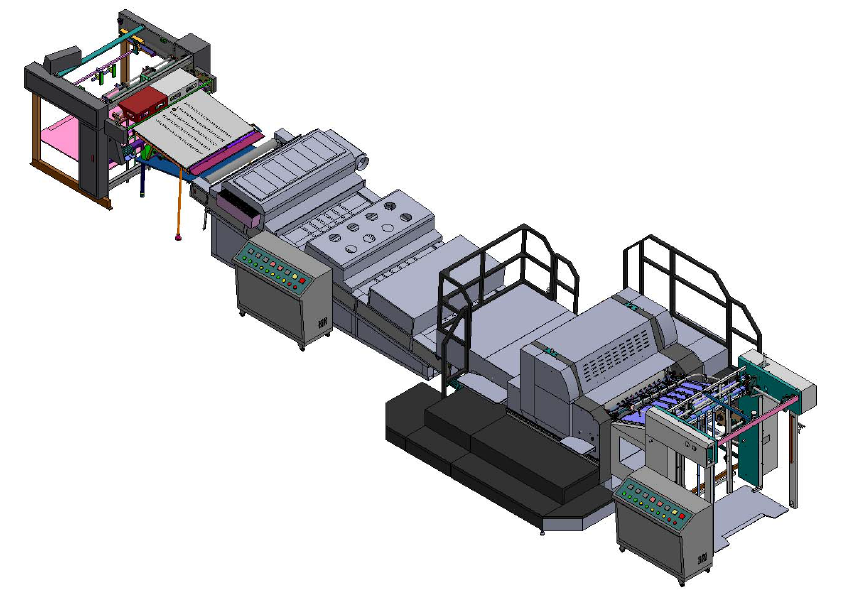

Tymi latest High Speed UV Spot Coating Machine, Model Ustar-102C has a max. coating speed of 8800 sheets/hr. The structure and design of Ustar-102 is different from the economic model Ustar-36, with improvement of the feeding system, transferring system, delivery gripper, frame, gears, transmission, lubrication, electricity...etc. to bear the high speed operation and to give better performance.

USTAR-102C FEATURES:

- Accurate spot coating registration with tolerance of +/- 0.5mm

- Double diameter impression cylinder reduces the surface tension of coating varnish, thus decreasing the roller marks but increasing gloss.

- Robust construction with 13 tons weight capable of 15000 cycles /hr.

- Offset configuration with under swing arm feeding system.

- Gears & shafts bearing in oil bath system while machine in production.

Equipment:

- High speed stream feeder

- Spot / full coater for UV varnish / water based (Aqueous) varnish coating

- Drying conveyor

- UV curing system

- IR drying system (option)

- Air condition (option)

- Delivery unit

Technical Specifications:

|

Max. Sheet Size |

730 x 1030 mm |

|

Min. Sheet Size |

340 x 406 mm |

|

Coating area |

720 x 1020 mm |

|

Paper thickness |

80 - 450 gsm |

|

Machine Speed |

Up to 8800 Sheets / hour |

|

Dimension (LxWxH) |

10436 x 3150 x 1865 mm |

|

Total Weights |

13750 kg |

|

Total Power required |

82.1 kw (UV) + 58.1 kw (water based) |

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email